|

Eyebolt Information

General

Information

Application / Installation

Inspection/Maintenance Safety

Safety Precautions

Rated Capacities

Rated Capacities Guidelines

General Information

|

Ken Forging Machinery

Eyebolts are manufactured to ASME B18.15 and tested to ASTM

A489 specifications.

|

|

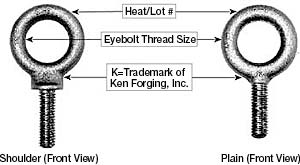

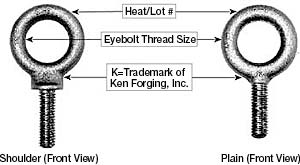

EYEBOLT TRACEABILITY

MARKINGS

|

Material Data

| Material |

Carbon Steel |

| Heat Treat |

Quench and draw |

| Grain Size |

5 or finer |

| Tensile |

65,000 PSI MIN -

90,000 PSI MAX |

| Yield |

30,000 PSI MIN |

| Elongation |

30% MIN |

| Reduction of Area |

60% MIN |

| Rated Catacity |

See

below |

|

Application

/ Installation Application

/ Installation

- The receiving hole should be counter-sunk

and be free and clear of any debris to assure proper seating.

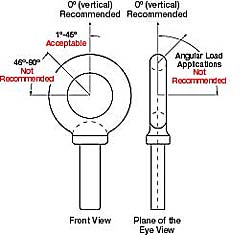

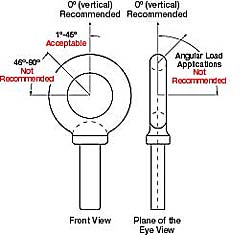

- LOADS SHOULD ALWAYS BE ALIGNED TO THE PLANE

OF THE EYE, not at an angle to the plane. A steel washer or spacer

may be used in conjunction with Shoulder Eyebolts to attain proper

load alignment. The thickness of the steel washer or spacer must

not exceed one thread pitch.

- Angular lifting should be avoided. Angular

lifts significantly reduce rated capacities. See Rated

Capacities/Guidelines.

- Check seating after applying an angular lift

since the initial lift may cause the bolt to back away from the

load. If such occurs, the Eyebolt should be unloaded & properly

reseated.

- For applications with untapped through-holes,

longer length Shoulder Eyebolts are recommended, using a steel

washer and nut for the required thread length of engagement.

- Shoulder Eyebolt tapped holes are to have

a threaded length which allows for full length of shank engagement

and clearance for the unthreaded portion of shank.

- Shoulder Eyebolts must be firmly seated and

flush against the mating surface; otherwise, the rated capacity

is reduced significantly. The use of a steel washer or spacer

is permissible and may be required; however, the thickness must

not exceed one thread pitch.

- Plain Eyebolt tapped holes are to be threaded

for full length engagement of the Eyebolt.

- Plain Eyebolts must have full thread shank

engagement, allowing for one-half turn for proper eye-alignment

to obtain rated capacities.

Inspection / Maintenance Safety

- Eyebolts should be inspected and installed

by a competent person who is knowledgeable about the application

and installation of Eyebolts.

- Each Eyebolt must be completely inspected

BEFORE each use for possible defects such as: distortion, bent

shank/threads, or incomplete/incorrectly formed threads. Periodic

inspection of Eyebolts is highly recommended.

- Eyebolts should not be painted or otherwise

coated when used for lifting; such coatings make it difficult

to inspect for defects or wear indicators.

- Eyebolts should not be left where they can

incur mechanical damage or corrosion.

- Destroy Eyebolts

when signs of bend, elongation, wear or damage are visible.

Such signs indicate that the Eyebolt has been stressed (overloaded)

beyond rated capacity. Never attempt to repair a stressed Eyebolt.

- Destroy Eyebolts

when they show any signs of alteration. Signs include:

gouging, undercutting, welding, etc.

- Proper Destruction

of an Eyebolt: crushing or cutting clear across the

eye of the Eyebolt.

Safety Precautions

- DO NOT work, stand or crawl around

the load of the Eyebolt. Ensure a safe distance from the load.

- DO NOT use wrenches, crowbars, etc.

to tighten Eyebolts. Hand tightening is recommended.

- DO NOT use a single Eyebolt to lift

a load that can rotate. Safety Swivel

Hoist Rings are recommended for such loads.

- DO NOT force hooks or any other fittings

into the eye; they must fit freely.

- DO NOT exceed the Rated Capacity.

- DO NOT SHOCK LOAD EYEBOLTS. Gradually

increase lifting of the load to minimize load-shock.

- DO NOT weld Eyebolts, or perform any

weld-repair on Eyebolts.

- DO NOT machine Eyebolts on the shank

or shoulder to achieve proper seating.

- DO NOT expose Eyebolts to extreme environmental

conditions, as they may adversely affect the Rated Capacity.

Rated Capacities

|

|

Shoulder Eyebolt Rated

Capacities

| Size |

0° Lbs. |

45° Lbs. |

46° + |

| 1/4 |

500 |

125 |

SAFETY

SWIVEL HOIST RINGS RECOMMENDED |

| 5/16 |

900 |

225 |

| 3/8 |

1,300 |

325 |

| 7/16 |

1,800 |

450 |

| 1/2 |

2,400 |

600 |

| 9/16 |

3,000 |

800 |

| 5/8 |

4,000 |

1,000 |

| 3/4 |

5,000 |

1,250 |

| 7/8 |

7,000 |

1,750 |

| 1 |

9,000 |

2,250 |

| 1 1/8 |

12,000 |

3,000 |

| 1 1/4 |

15,000 |

3,750 |

| 1 1/2 |

21,000 |

5,250 |

| 1 3/4 |

28,000 |

7,000 |

| 2 |

38,000 |

9,500 |

| 2 1/2 |

56,000 |

14,000 |

| NOTE:

Plain Eyebolt angular rated capacities are significantly

lower than Shoulder Eyebolt rated capacities; therefore,

angular lifting is not recommended. |

|

Rated Capacity Guidelines

- The minimum threaded shank length of Eyebolts

must be one thread diameter to attain the rated capacity.

- No greater load should be applied to an Eyebolt

than the Rated Capacity listed.

- Angular lifts significantly

reduce Shoulder Eyebolt Rated Capacities. Shoulder

Eyebolts should not be used for angular lifts greater than 45†;

Safety Swivel Hoist Rings are recommended for such applications.

- Plain Eyebolts are

not recommended for angular load applications. Safety

Swivel Hoist Rings are recommended for such applications.

|

![]()